It's rather simple really.

Resistance increases as distance increases. So the more wraps you do around the wick; the higher your resistance will be.

Resistance is also dictated by wire gauge (thickness) in the sense that electricity (electrical current) is the movement of electrons on the wire from point A to B... So thinner (higher Gauge) wire will have more resistance than thicker wire (lower Gauge) as it has less material (electrons).

Final resistance of a coil can be "sort of predicted" with a bit of practice and some math.

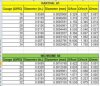

Here's a chart of the resistances of each of the Gauges of wire per "lenght".

View attachment 258701

With that chart and a bit of ingenuity one can predict what the resistance on any given coil would be. Just take your wick; you should know what diameter it is (or at least an approximation of it... When in doubt go with the wickhole diameter as that is known).

With that diamter; you can calculate the circumference.

Warning: Math below

Area of a Circle

A = πr²

Circumference of a Circle

C = 2πr or πd -> Where "d" is the diameter of the circle (wick hole diameter).

Now that you know the circumference of the wick hole; you then figure out how many wraps you plan on doing and multiply that number by said circumference. That gives you a length that you can then look up on the chart and approximate the expected resistance.

Example:

- Kanthal A1 - 28 Gauge Wire

- 2.5mm diameter wick hole.

- 5 wraps coil.

Circumference of the wick hole

Cw = π * 2.5mm => 7.85mm

Number of wraps * Cw

5 * 7.85mm = 39.27mm

Add 5mm on each end for connection to the posts on the atty.

Total lenght = 49.27mm (Round this up to 50mm)

We now have the length of wire that will be used. Look it up on the chart.

28 Gauge Kanthal A1 is 0.017Ω/mm

50mm * 0.017Ω/mm = 0.85Ω

And there you have it. A 5 wrap coil of 28 Gauge Kanthal A1, done around a 2.5mm wick should come out at 0.85Ω. Give or take a few tenths of an Ω.

Hope this helps.

Seebs